A torque wrench is a specialized socket wrench tool designed to tighten fasteners to a predetermined torque value, ensuring consistency and preventing over or under-tightening of the fasteners, which can lead to issues like stripped threads or loosening. A torque wrench is used where the tightness of screws and bolts is a crucial parameter of assembly or adjustment. It allows the operator to set the torque applied to the fastener to meet the specification for a particular application.

source.image: Deconstructed

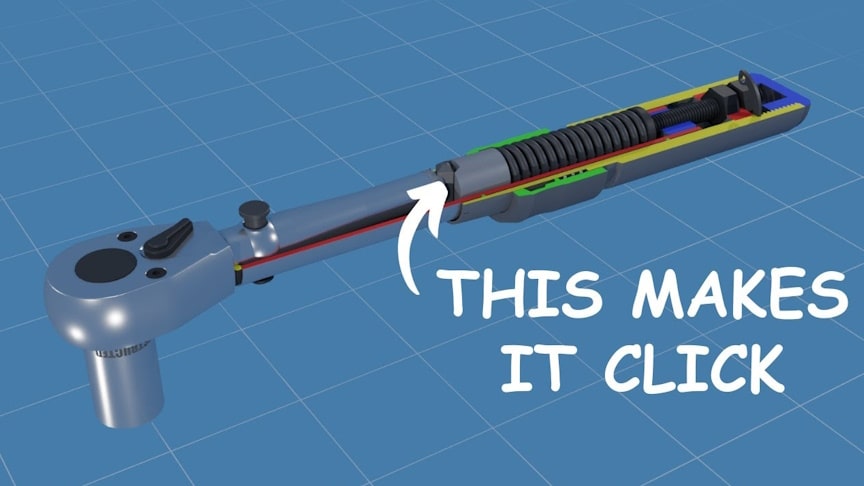

This permits proper tension and loading of all parts. In this 3D animated video, we’ll see how to use a ratcheting click-type torque wrench and look at the mechanism inside to see how it works. Click-type torque wrenches are the most commonly used type of torque wrench available.

A more sophisticated method of presetting torque is with a calibrated clutch mechanism. One common form uses a ball detent and spring, with the spring preloaded by an adjustable screw thread, calibrated in torque units. The ball detent transmits force until the preset torque is reached, at which point the force exerted by the spring is overcome and the ball “clicks” out of its socket.

Advertisement

This design yields greater precision as well as giving tactile and audible feedback. The wrench will not start slipping once the desired torque is reached, it will only click and bend slightly at the head; the operator can continue to apply torque to the wrench without any additional action or warnings from the wrench.