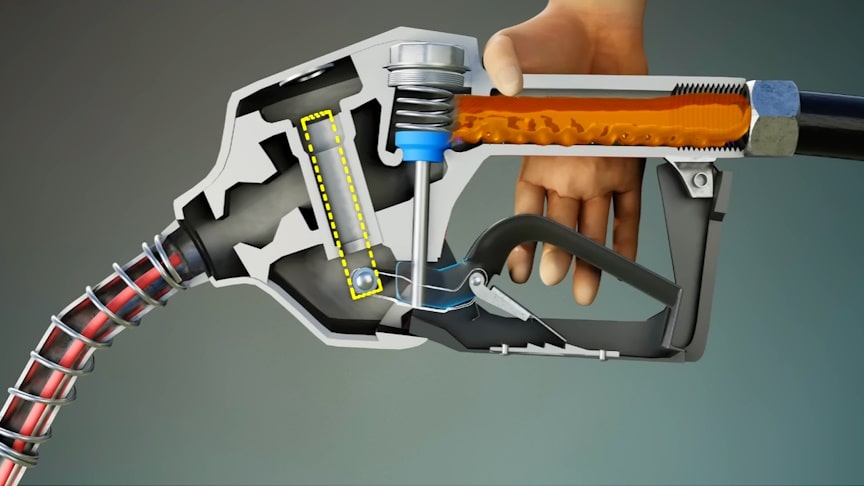

The fuel nozzle uses the liquid pressure to generate a fine hollow spray to provide the engine with atomized fuel, thereby improving the fuel efficiency. Nozzles are attached to the pump with flexible hoses, so they can reach the vehicle’s filler inlet.

source.image: Lesics

The hoses are robust to survive heavy wear and tear, including exposure to weather and being driven over, and are often attached using heavy spring or coil arrangements to provide additional strength. A breakaway valve is also fitted to the hose so that the nozzle and hose will detach and fuel flow stop if a motorist drives off with the nozzle still in the filler. Watch the video from Lesics for more info:

The nozzle has a valve system that controls the flow of fuel. When the trigger is activated by inserting the nozzle into the fuel tank, the valve opens to allow fuel to flow. Automatic fuel nozzles are designed with a shut-off mechanism to stop the fuel flow when the tank is full. Some nozzles use a mechanical mechanism that relies on pressure changes, while others may use electronic sensors to detect fuel levels.

Advertisement

Automatic fuel nozzles often come with safety features, such as a latch that can be engaged to keep the trigger in the “on” position without the need for the user to continuously hold it.I am sure you are pretty impressed with the engineering behind the gas nozzles. SolidWorks helped me a lot to understand the technology behind the gas nozzles