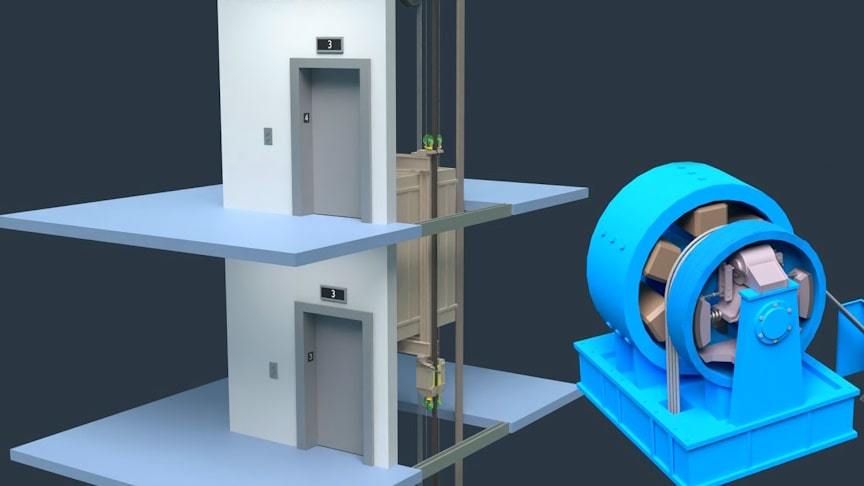

Traction lifts are one of the most common systems for large lifts and elevators. Traction lifts are referred to as all sorts of things, including cable lifts, counterweight lifts or rope lifts. The main components of a traction lift are: cables or ropes, a sheave, or pulley, counterweight, motor.

source.image(PrtSc): Jared Owen

Aodern-day elevator consists of a cab (also called a “cabin”, “cage”, “carriage” or “car”) mounted on a platform within an enclosed space called a shaft or sometimes a “hoistway”. The motor turns the sheave, which rotates the ropes around the wheel. The ropes are attached to the elevator car and the counterweight. Come learn how a traction elevator work! We’ll also explore history and different types of elevators.

As the sheave rotates, the ropes move the elevator car up or down. The counterweight is used to balance the weight of the elevator car and helps to reduce the amount of power required to move the elevator. The speed of a traction elevator is determined by the size of the motor and the size of the sheave.

Advertisement

Geared traction machines are driven by AC or DC electric motors. Geared machines use worm gears to control mechanical movement of elevator cars by “rolling” steel hoist ropes over a drive sheave which is attached to a gearbox driven by a high-speed motor. These machines are generally the best option for basement or overhead traction use for speeds up to 3 m/s (500 ft/min).