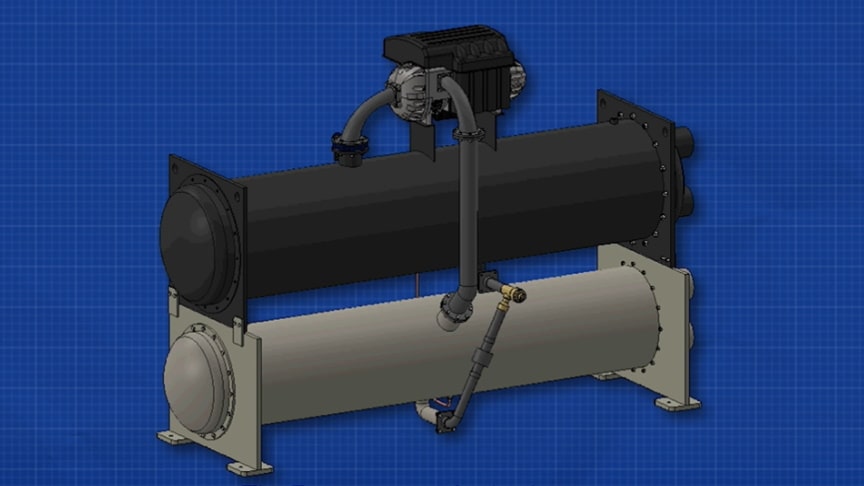

The Turbocor, oil-free compressor incorporates an inverter-driven, permanent magnet motor and magnetic bearings. Within the compressor, efficiency is affected by the compressor’s isentropic efficiency, the motor and the bearings.Turbocor chiller, learn how turbocor chillers work, the main components and centralised cooling systems.

source/image(PrtSc): The Engineering Mindset

Dual impeller, variable frequency drive, VFD, IGBT, electronic expansion valve EEV, liquid level sensor, air handling unit AHU, fan coil unit FCU, inlet guide vane IGV. Water cooled chiller, air cooled chiller. centralized cooling system. Chilled water, condenser water. Evaporator, condenser. Watch the video from The Engineering Mindset for more info:

Traditional induction motors of this size are in the 92% efficiency range. The Turbocor compressor’s permanent magnet DC motor, with its completely integrated variable-speed drive, provides an efficiency of between 96 to 97%.End users can take full advantage of the benefits of oil-free, magnetic bearing, centrifugal compressor technology in high lift applications previously limited to positive displacement compressors.

Advertisement

The TTH and TGH models cannot only operate in demanding high lift applications, but also offer significant benefits versus typical screw compressor chillers. These benefits include higher efficiency, lower sound levels, greater compactness, and lighter weight versus comparable fixed-speed compressors, allowing for easier service and installation. As with all Danfoss Turbocor compressors, the oil-free technology maintains high-efficiency and consistent performance over the life of the compressor./Danfoss