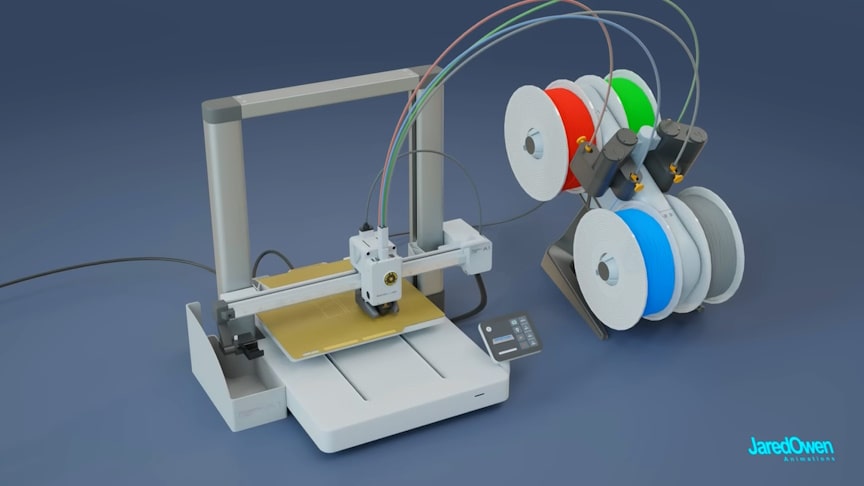

3D printing is a process that uses computer-aided design, or CAD, to create objects layer by layer. 3D printing uses specialized equipment to create solid, three-dimensional objects from a digital file.

source.image: Jared Owen

How Does 3D Printing Work? It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library. Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software. When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

Thee 3D laser printer first sprays solid powder or molten liquid material to solidify into special flat layers. After the first layer is solidified, the 3D laser printer head returns to form another thin layer outside the first layer. After the second layer is solidified, the printer head returns again to form another thin layer outside the second layer.

Advertisement

Repeat this process and ultimately stack thin layers into 3D objects. Due to high printing accuracy, the quality of printed models is naturally good. 3D printing technology realizes the seamless connection of CAD/CAM and truly realizes the integration of design and manufacturing. It is a typical embodiment of digital design and manufacturing technology.