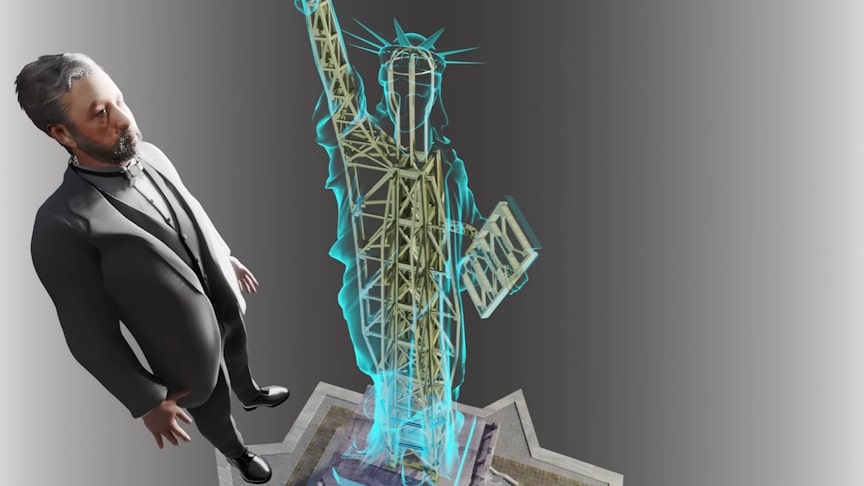

Let’s explore all the engineering secrets which made the Statue of Liberty possible around 140 years back. The copper-clad statue, a gift to the United States from the people of France, was designed by French sculptor Frédéric Auguste Bartholdi and its metal framework was built by Gustave Eiffel. The statue was dedicated on October 28, 1886. Eiffel wanted the structure to be flexible enough to give the monument the elasticity to withstand the strong ocean gusts. So inside the statue he built an iron truss tower – the first, invisible suit of armour.

source.image: Lesics

It was attached to a second suit of armor the statue’s exterior by iron bars ending in metal ribbons that were welded onto the external copper. A technique called repousse, which is a technique for creating sculptural forms by hammering sheet metal inside molds was used to make the framework. Watch the video from Lesics:

Lighter than cast metal, repousse was the only method available that would allow for such a monumental work to be shipped overseas. The Statue of Liberty stands 305 feet tall, and used 31 tons of copper and 125 tons of steel. Winds of 50 miles per hour cause the statue to sway 3 inches and the torch to sway 5 inches.

Advertisement

Eiffel opted not to use a completely rigid structure, which would force stresses to accumulate in the skin and lead eventually to cracking. A secondary skeleton was attached to the center pylon, then, to enable the statue to move slightly in the winds of New York Harbor, and, since the metal would expand on hot summer days, he loosely connected the support structure to the skin using flat iron bars or springs,= which culminated in a mesh of metal straps, known as “saddles”, that were riveted to the skin, providing firm support.