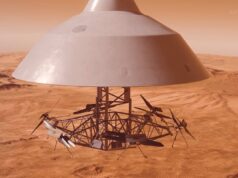

Designed by Hidromek Design Studio the HMK Vision Compactor provides its operator with shape – shifting drum and rear tires providing adaptable traction to different ground conditions, a 360 degree rotational cabin, a seat acting independently from cabin, and ” Ground Hardness Tester (GHT)”, which analyzes ground conditions and sets the drum and tires!

source/image(PrtSc): Hidromek Design Studio

Hakan Telesik, Hidromek’s design studio executive, believes that this product would be a good way to open up Hidromek’s path to the road construction segment. HMK Vision Compactor is a concept that signals the way of soil compactors in ten years along with the technological advancements.

source/image(PrtSc): Hidromek Design Studio

Soil compactors are used with standard or special attachments according to varied ground conditions. HMK Vision Compactor combines different attachments in single drum which includes a mechanism which is able to do both loose ground compaction and tight ground compaction without intervention and interception of the operation.

Advertisement

Operator can combine different attachments in a single “Shape-Shifting” drum with 17-degree oscillation, saving a great deal of time and labor.Since the mechanism responds to magnetic force, it causes ribs to arise from the drum. This method allows the machine to efficiently perform compaction of both loose and densely packed ground without any help from operator. The Ground Hardness Tester (GHT) feature would automatically activate the mechanism.

Instead of changig the drum, shape shifting dum saves great anount of time, not only time saving, but also significant amount of labour is saved.Vision Compactor combines different atachments in single durum which includes a mechanism which is able to do both loose ground compaction and tighter ground compaction without interventation and intereption of the operation.