How do scroll compressors work? What are the main parts, the different types and controls.Thanks to their unique design, the DSG scrolls deliver equivalent capacity to their R410A/R32/R454B alternatives, with excellent efficiency, and without footprint increase.

source.image: The Engineering Mindset

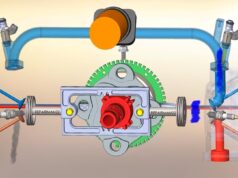

A scroll compressor also called spiral compressor, scroll pump and scroll vacuum pump is a device for compressing air or refrigerant.It is used in air conditioning equipment, as an automobile supercharger where it is known as a scroll-type supercharger and as a vacuum pump.

A scroll compressor uses two interleaving scrolls to pump, compress or pressurize fluids such as liquids and gases. The vane geometry may be involute, Archimedean spiral, or hybrid curves.Often, one of the scrolls is fixed, while the other orbits eccentrically without rotating, thereby trapping and pumping or compressing pockets of fluid between the scrolls.

Advertisement

An eccentric shaft can provide the orbital motion but the scroll must be prevented from rotating, typically with an Oldham-type coupling, additional eccentric idler shafts, or a bellows joint (particularly for high-purity applications). Another method for producing the compression motion is co-rotating the scrolls, in synchronous motion, but with offset centers of rotation. The relative motion is the same as if one were orbiting.