Bridges made of concrete are going to expand and contract slightly for a number of reasons, including temperature changes, shrinkage of the concrete, settlement, ice and even the weight of vehicles. Bridge expansion joints are what allow the concrete to naturally expand and contract without cracking.

source: azdot

The rubber expansion joints are placed at the end of a bridge where it meets up with the freeway. These connectors give the concrete just enough space to move and avoid concrete cracks.

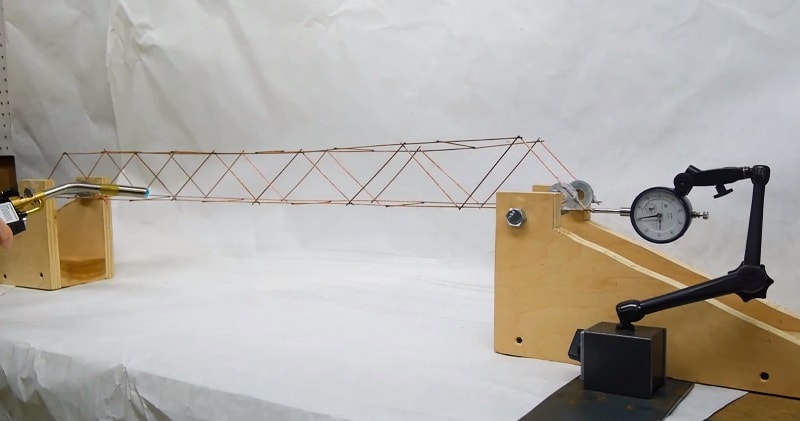

source/image: Practical Engineering

Expansion joints come in all shapes and sizes, from clay bricks to molded rubber. Some forms of construction, like railways or air ducts, have specialized breather joints meant to deal with their unique thermal stresses.

source/image: Practical Engineering

The rubber expansion joints are placed at the end of a bridge where it meets up with the freeway. These connectors give the concrete just enough space to move and avoid concrete cracks.

Advertisement

Most people have a certain intuition about thermal expansion, but you may not have considered how engineers design to accommodate it on large civil structures. Practical Engineering explain why bridges move.

The video gives a quick overview on this important consideration that engineers must account for when designing infrastructure like pipelines, bridges, and even sidewalks.