Car engines run at high speeds, so a reduction in gearing is necessary to transmit power to the drive wheels, which turn much more slowly.The transmission allows the gear ratio between the engine and the drive wheels to change as the car speeds up and slows down. You shift gears so the engine can stay below the redline and near the rpm band of its best performance.

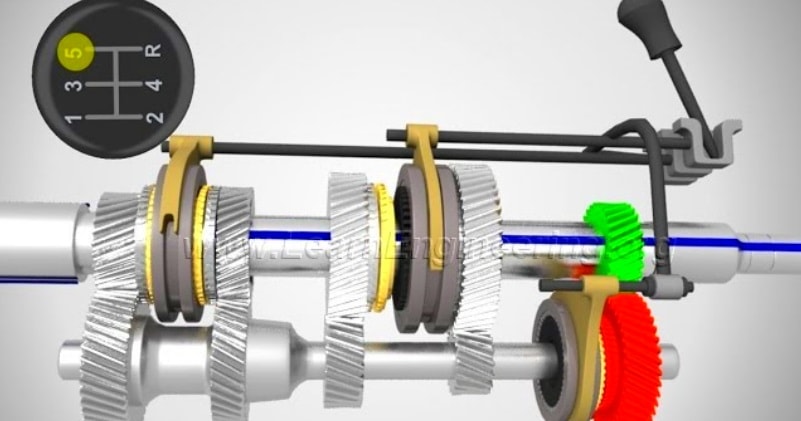

source/image: Learn Engineering

Working of a Manual transmission is explained in an illustrative and logical manner in this video with the help of animation. Here the working of Sliding mesh and synchromesh transmissions are well illustrated. This video from “Learn Engineering” also explains the working of a reverse gear.

Modern cars with manual transmissions have four or five forward speeds and one reverse, as well as a neutral position.Everything starts at the engine, where the flywheel transmits power to a clutch disc that’s sandwiched between the pressure plate. The clutch disc is splined to the transmission input shaft, which rotates the gear assembly.

Advertisement

A selector fork allows the driver to choose which gear to select, and power will then be routed to an output shaft and then a differential, ultimately reaching the driven wheels.The engine drives the input shaft, which drives the layshaft. The layshaft rotates the gears on the mainshaft, but these rotate freely until they are locked by means of the synchromesh device,the synchromesh device which is actually operated by the driver, through a selector rod with a fork on it which moves the synchromesh to engage the gear.