The notchers are very useful as they are used to remove a piece of the tube in order to fit precisely on another tube without leaving any gap between them and so that their welding to be accurate.There are various kinds of notcher at the market and each and every one has its own advantages and disadvantages.

source/image(PrtSc): Make it Extreme

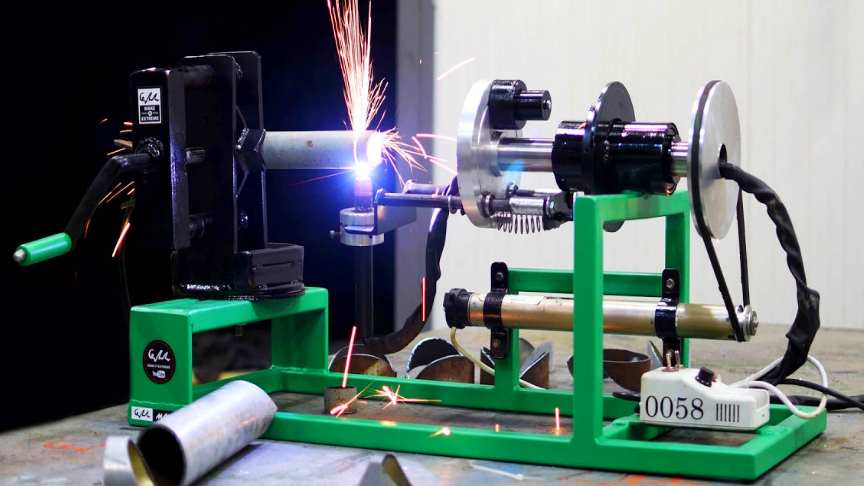

In particular, our construction uses the plasma cutter as a cutting tool. To start with, we first made a frame made of a square tube of 30 x 30 x 2mm on which we placed a tube with slots to pass a bearing through the two edges. Then, through the bearing we passed a perforated shaft, which at its back side a pulley was placed and it was connected on the motor with a strap.

Initially, we used a motor taken by car wipers but then we preferred an AC motor having the potential of moving both on the right and on the left. The motor was connected with a potentiometer to regulate the speed of its rotation and with a switch that chooses the rotational direction as well as the activation of the motor.

Advertisement

Therefore, by activating the motor the perforated shaft rotates on the direction that we want and at the speed that we wish. After we had achieved our goal and this function, we put an aluminum flange lined with linear bearing at the front side of the perforated shaft. The linear bearing is used for ensuring a forward and backward move in our machine. Moreover, using these bearings, we managed to make a basis for the plasma cutter. At the back side of the basis, there is a bearing that follows a guiding ring to achieve a particula move according to the guiding ring. makeitextreme