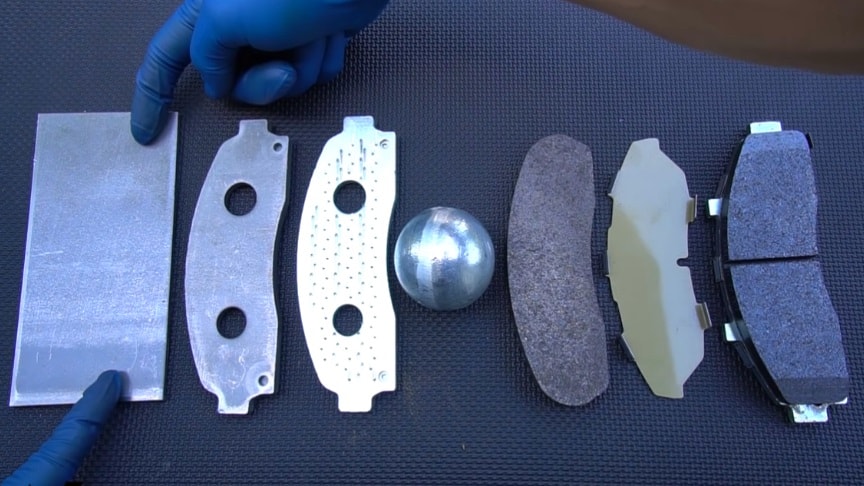

To make brake pads, we start out with raw pickled and oiled steel. The steel gets stamped into a brake pad backing plate which gets analyzed to make sure it meets OEM specifications.

source/image(PrtSc): ChrisFix

Brake pads aren’t just slabs of metal. They’re typically made of iron, copper, steel and graphite all mixed and together and bonded to form the pad material. Watch the video from ChrisFix for more info:

Next the brake pad backing plate goes to the NRS press to get a mechanical attachment. Then the backing plates get galvanized and finally brake pad friction material is added.

Advertisement

The manufacturer can add and friction material they want such as semi-metallic, organic, or ceramic friction material. Lastly the shim is made and installed on the brake pad and they can be sent to testing! When it is all said and done, I took the brake pads we made and installed them on my truck with new brake rotors!