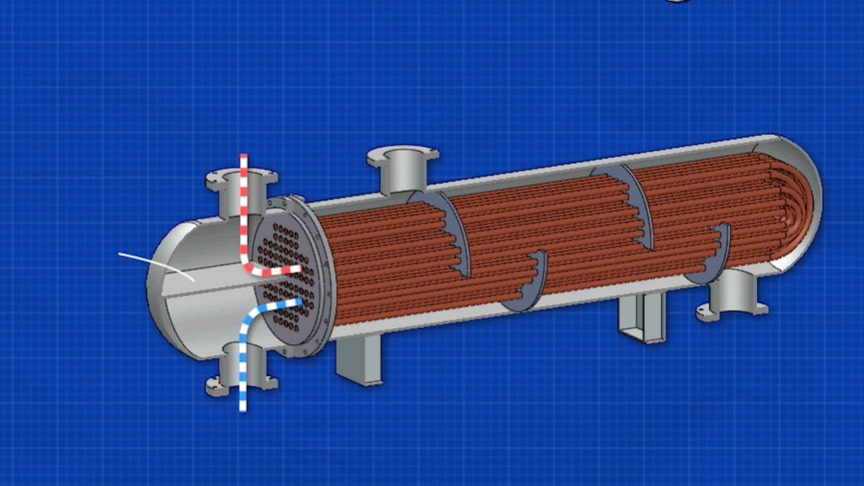

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes.The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.

source/image(PrtSc): The Engineering Mindset

They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment.Industrial heat exchangers explained, learn the different types of heat exchangers used and how they work with examples.

There are three common kinds of heat exchangers. They can all be effective in a variety of heat transfer applications, but optimizing efficiency, cost and space depends heavily on the particular process in which the heat exchanger is installed.1. Double-pipe heat exchanger (a) When the other fluid flows into the annular gap between two tubes, one fluid flows through the smaller pipe. The flow may be a current flow or parallel flow in a double pipe heat exchanger. (b) Parallel flow, where at the same point, the hot and cold liquids join, flow in the same direction and exit at the same end.

Advertisement

2. Shell-and-tube heat exchangerThe main constituents of this type of heat exchanger seem to be the tube box, shell, the front rear end headers, and baffles or fins.3. Plate Heat Exchanger A plate heat exchanger contains an amount of thin shaped heat transfer plates bundled together. The gasket arrangement of each pair of plates provides two separate channel system. Each pair of plates form a channel where the fluid can flow through. The pairs are attached by welding and bolting methods. The following shows the components in the heat exchanger./wikipedia