Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

source/image(PrtSc): PaulsonTraining

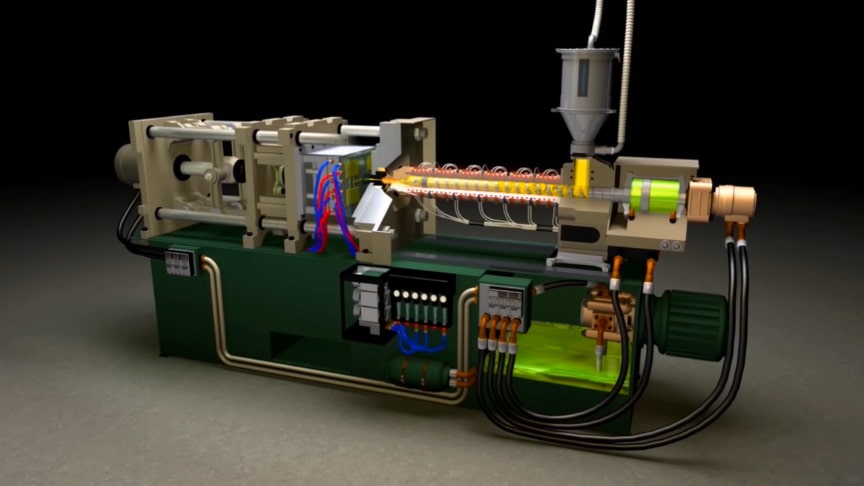

Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. Watch the video from PaulsonTraining:

After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part.

Advertisement

Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Injection moulding uses a special-purpose machine that has three parts: the injection unit, the mould and the clamp.wikipedia