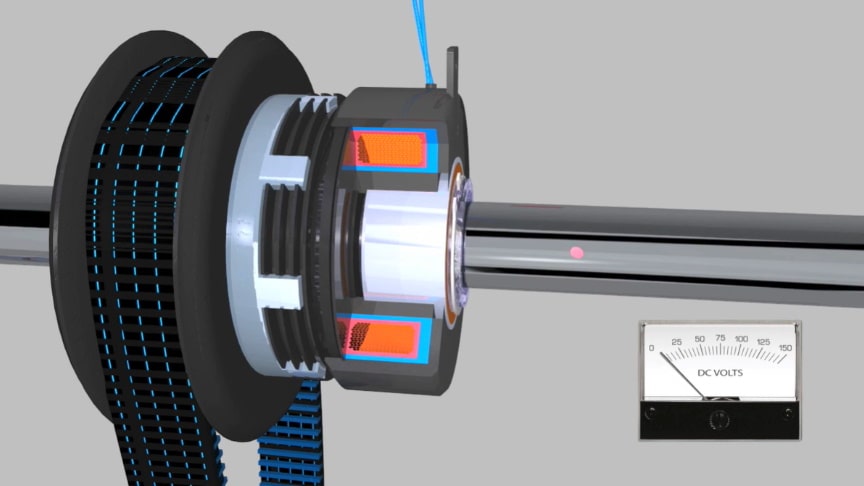

A multi-plate clutch is a type of clutch in which the multiple clutch plates are used to make frictional contact with the flywheel of the engine in order to transmit power between the engine shaft and the transmission shaft of an automobile vehicle.

image: oguraindustrial

A multi-plate clutch is used in automobiles and in machinery where high torque output is required.In bikes and scooter multi-plate clutch is used due to the limitation of compact gearbox used in bikes and scooter.One of them is the engine shaft and another one is the transmission shaft. Friction takes place in the engine by the clutch plates. This friction makes high torque.

The high amount of torque can be generated by the multi-plate clutch due to the number of plates.When the clutch pedal is depressed, the fulcrum at its inner end spins, causing the inner splined sleeve through which the pressure plate is connected to travel outward, applying pressure to the thrust springs. The thrust springs move as a result of this force, releasing tension on the pressure plate and removing the frictional force between the pressure plate, clutch plate, and flywheel.

Advertisement

The plates are alternately fitted to the engine crankshaft and gearbox shaft. They are firmly pressed by strong coil springs and assembled in a drum type casing.Multi-Plate Clutches are two types. These clutches are used in automatic transmission.Multi-Plate wet Clutch When the clutch is operated in an oil bath, it is called a wet clutch. Multi-Plate dry Clutch When the clutch is operated dry it is called dry clutch. This clutch has plates with friction material the same as in single plate clutch.