Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy.In pneumatics, cylinders belong to the most important actuators.

source/image(PrtSc): learnchannel

Controlled by way-valves in their direction of movement, they can grip and deposit these workpieces in a controlled manner. Even rotational movement can be executed. It is up to you to choose the right cylinders in type and size.

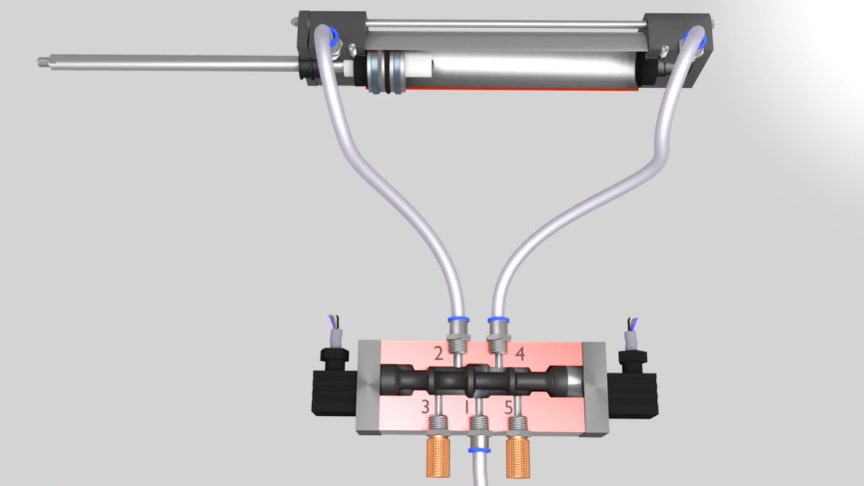

Once actuated, compressed air enters into the tube at one end of the piston and imparts force on the piston. Consequently, the piston becomes displaced.The main components of a typical pneumatic cylinder are: cap-end port (A), tie rod (B), rod-end port (C), piston (D), barrel (E), and piston rod (F). Figure 1 and the function described below is for a double-acting pneumatic cylinder.

Advertisement

Although pneumatic cylinders will vary in appearance, size and function, they generally fall into one of the specific categories shown below. However, there are also numerous other types of pneumatic cylinder available, many of which are designed to fulfill specific and specialized functions. There are single-acting cylinder, double-acting cylinders, multi-stage, telescoping cylinders./wikipedia