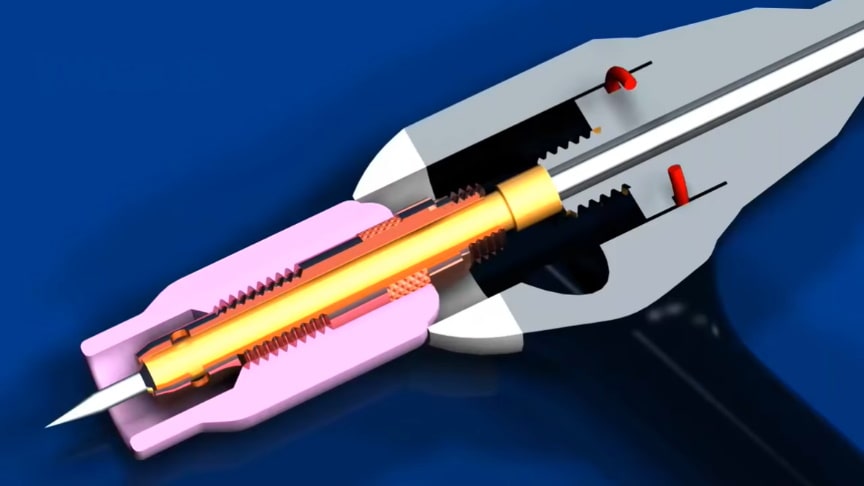

Gas tungsten arc welding GTAW, also known as tungsten inert gas TIG welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas argon or helium.

source/image(PrtSC): WeldNotes.com

A filler metal is normally used, though some welds, known as autogenous welds, or fusion welds do not require it. When helium is used, this is known as heliarc welding. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

In the TIG Welding process, an arc is produced in between the non-consumable tungsten electrode and workpiece which is to be joined. The arc so produced creates an intense heat that melts the two metal pieces and fuses them together to form a strong weld by the use of a filler metal.

Advertisement

The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques./wikipedia