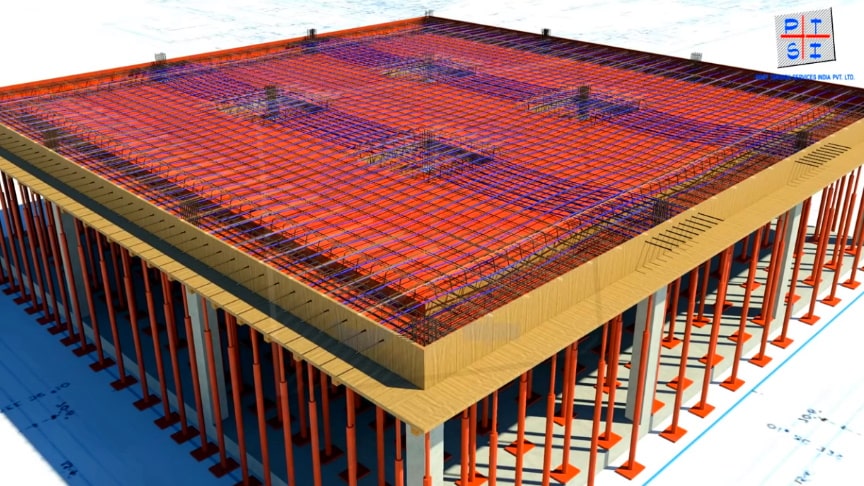

An animation movie which illustrates almost all the activities related to mono strand unbonded post tensioning system. An installation, stressing and post construction activities such as making a cutout in the existing post tensioned floor.

source/image(PrtSc): Post Tension Services..

Unbonded post-tensioning differs from bonded post-tensioning by allowing the tendons permanent freedom of longitudinal movement relative to the concrete. This is most commonly achieved by encasing each individual tendon element within a plastic sheathing filled with a corrosion-inhibiting grease, usually lithium based.

Anchorages at each end of the tendon transfer the tensioning force to the concrete, and are required to reliably perform this role for the life of the structure.

Advertisement

Unbonded post-tensioning can take the form of:Individual strand tendons placed directly into the concreted structure (e.g., buildings, ground slabs).Bundled strands, individually greased-and-sheathed, forming a single tendon within an encapsulating duct that is placed either within or adjacent to the concrete (e.g., restressable anchors, external post-tensioning).