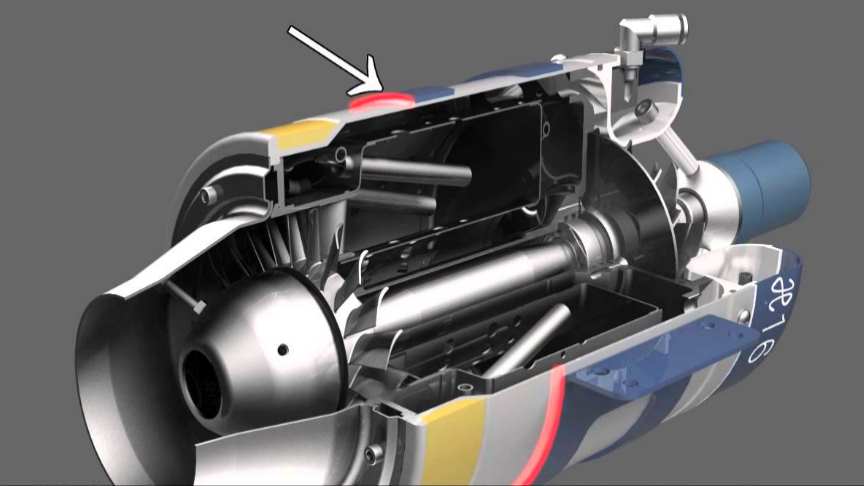

Hyblturbines introduces the new upgraded version of our engine H16BL2. Key difference between H16BL and H16 is the new machined compressor wheel, designed in house. This means 1kg more thrust and increased life of the impeller wheel which is made by 5 axis milling from high strenght aluminium alloy.

source/image(PrtSc): Hybl Turbines

For model jet engines, this pre-spinning is accomplished by either blowing compressed air into the front of the engine by say a leaf blower, spinning the engine with an external high speed electric starter,using a permanently installed small electric starting motor that is mounted onto the front of the model turbine engine. watch the video from Hybl Turbines for more info:

This electric motor uses something called a Bendix engagement clutch so the only time it’s mechanically connected to the output cone on the front of the compressor shaft is when the electric motor is powered up and spinning.Once the turbine starts, the electric starting motor shuts off and the Bendix disengages as there is no more torque inertia to keep it pressed up against the cone.

Advertisement

The rc engines sucks a lots of air, compress it, add fuel to the compressed air, ignite the compressed air/fuel mixture, and blow it out the exhaust nozzle/sThe end result is lots of hot compressed expanding air exiting the back of the engine. This turbine exhaust is converted into a high speed jet of air by forcing it through a propelling nozzle and the result is thrust. / via/read more: rchelicopterfun

Parameters:

- Max Thrust (122kRPM): 17 kg + -3% (ISA SL)

- Fuel Consumption: ~470 g/min (SFC ~0.460 g/kp/s)

- Fuel: JetA1 + 4-6% Mobil DTE Oil Light or MIL-L-23699

- Diameter: 111 mm

- Total Lenght: 273 mm

- Engine weight: 1610 g

- Operating voltage: 7,8-8,4V (LiPol 2s)