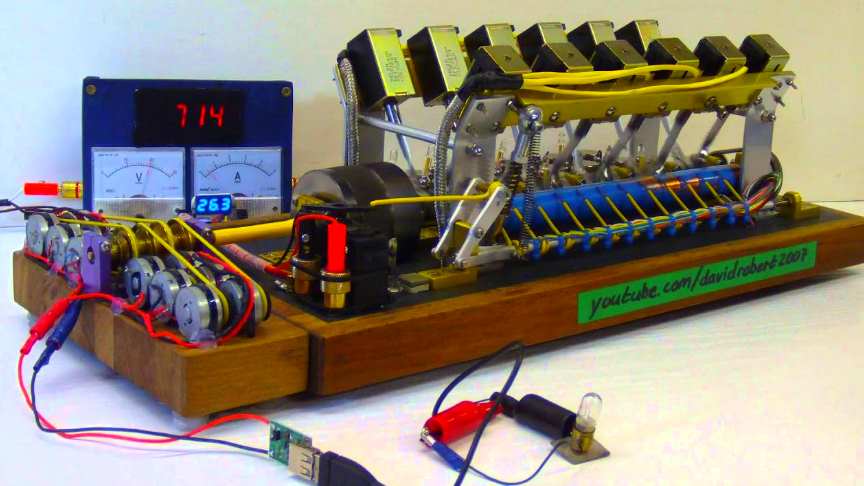

A solenoid engine uses the magnetic pull of solenoids to turn a crankshaft, and resembles the architecture of an internal combustion engine.The crankshaft on this engine is made up of one hundred and forty individual parts bolted together, and is fully counterweighted to balance the rotational mass.

source/image(PrtSc): davidrobert2007

The flywheel is an old drill / lathe chuck of some sort (army surplus), the engine has a tachometer pulse generator on the rear of the timing / distributor shaft to run the red LED tachometer, it uses Meccano timing chain and sprockets, and has a key ignition switch for added style.

This engine can run both as a four stroke or as a two stroke, and can switch while running. This engine does not develop much torque, certainly much less torque than a standard rotary electric motor can produce, for the equivalent power input – for this reason the solenoid engine is just a novelty and an educational model.I built this engine for fun, from mainly scrap metal and wood, and using mostly hand tools, and a basic drill press, during autumn 2014.

Advertisement

My v12 solenoid motor attached to a homemade generator set. The generator is made up of twelve 6 volt brushed motors wired together in parallel. The output voltage is boosted from 1.2 volts to 5 volts by an inline dc-dc boost module.via/read more: davidrobert2007

- Engine Technical details:

- Type: 60 degree V12 electric piston engine

- Maximum RPM: 3,200 RPM

- Input voltage: 24 volts dc

- Speed controller: Mechanical PWM

- Cylinder bore diameter: 8mm

- Piston stroke length: 10mm

- Total theoretical displacement: 6cc

- Firing order: 1, 12, 5, 8, 3, 10, 6, 7, 2, 11, 4, 9 (Same as old type Ferrari)

- Main bearing size: 4x9x4 mm (684zz)

- Big end bearing size: 4x9x4 mm (684zz)

- Flywheel mass: 900g

- Switching transistors: 2N3055

- Solenoid model: SOLEN 121E16530 (with built in flyback diode)

- Total mass of engine: 6kg approximately

- Exhaust emissions: zero